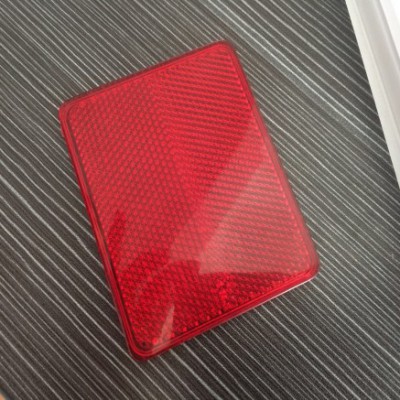

spare parts box mould

- BrandJUNXIN

- Country of OriginChina

- StatusIn stock

- TypeNew

- MOQ1 / Sets

- PriceUSD$ 6000 / Sets

- CategoryMould Manufacturer > Household Mould

- Mold SteelP20, 718H, 2738H etc.

- Mold BaseS50C or LKM

- Mold CavityMulti Cavity

- Runner TypeHot / Cold runner

- Mold Life

- Shaping Mode

- Payment TermsTT

- Delivery Period50 Days

Product Keywords:

spare parts box mould, crate mould

1. Plastic injection molds have a high degree of precision and stability

Plastic injection mould can meet the requirements of precision manufacturing. Whether it is the precise control of the product size, or the parts with the slightest difference, plastic injection molds can easily handle. This provides manufacturers in various industries with a highly efficient production guarantee, ensuring product consistency and quality stability.

2. Plastic injection molds have high productivity and good economic benefits

Compared with the traditional manufacturing process, plastic injection molds can achieve mass production, and greatly shorten the entire production cycle. This not only improves the production efficiency, but also reduces the product manufacturing costs, creating great economic benefits for the enterprise.

3. Plastic injection molds with high durability and maintainability

It is made of high-quality materials with excellent abrasion and corrosion resistance, and can maintain stable performance for a long time. At the same time, the plastic injection mold is also characterized by easy maintenance and replacement of parts, reducing maintenance costs and extending service life.

4. Plastic injection mold taking into account the sustainable development of environmental protection

In the use of plastic injection mold for manufacturing, the mold can be reused many times, reducing the pollution of the environment and waste of resources. In addition, the plastic injection mold in the production process requires less material, can significantly reduce the waste generated for the green environmental protection to make a positive contribution.