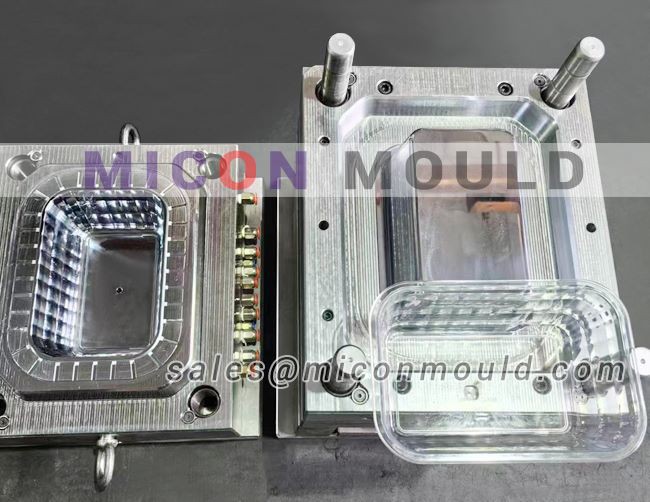

PET clear box mould

- BrandMicon Mould

- Country of OriginChina

- StatusIn stock

- TypeNew

- MOQ1 / Sets

- PriceUSD$ 8500 / Sets

- CategoryMould Manufacturer > Household Mould

- Mold SteelP20, 718H, 2738H etc.

- Mold BaseS50C or LKM

- Runner TypeCold runner

- Mold LifeMore than 800K shots

- Shaping ModeInjection Molding

- Payment TermsTT

- Delivery Period55 Days

Product Keywords:

PET box mould, PET storage box mould, PET basket mould

PET clear box product drawing description

The parts draft designs provide by clients.

After received the initial part designs or product sample from client, we will check the details, analyse the part design,plastic raw material and get general idea of proper mold structure in mind. If client require us make mold same as part sample,we are able to scan part and complete whole product 3D drawing. If one product without sample,it's new developed item, client share us their design, both 2D and 3D are availble. In case our engineer found mistake/unproper design on some positions,we will share our suggestions and help client improve product drawing.

1. PET clear box mould machining

mould steel procurement

Once moulds design confirmed by client, we can go on the mould steel purchasing and cutting. Steel plates are cut by steel supplier. We just send the steel purchase order to the supplier. The steel detail sizes and detail tooling request already marked on the purchase order sheet. Steel cutting is the first step of the mould tooling. Steel cutting job were done by steel supplier factory. Before the steel plates delivered to our factory, we will check the steel hardness. Inspect the steel hardness can check the steel quality. As every different steel have their own hardness level. If hardness can match the steel which ordered, means that steel is exact what you order. Our factory Taizhou Xiongshi Plastic Mould never use fake steel or cheaper than quoted steel to make moulds.

2. PET clear box mould rough tooling

For small dispenser parts moulds, the main rough tooling machine is CNC milling tooling. But for some big parts mould, including bumper mould, use tooling centre to tool the mould. As that machine tool big mould, much faster. After rough tooling,moulds will be going on with precise tooling, including cnc high speed milling tooling and cnc engraving tooling.

3. PET clear box mould precise tooling.

Precise tooling include cnc engraving tooling, high speed cnc milling tooling, EDM tooling, EDW tooling, etc.

CNC engraving tooling include high speed, middle speed and normal speed. The tooling precision high speed > middle speed > normal speed. So when parts require high precise, means tooling require high speed cnc engraving tooling. At the same time, the tooling cost high speed > middle speed > normal speed. So parts sizes tolerance request higher, the tooling cost higher.

Some sizes, like ribs, sizes are very small and narrow, can not be directly tooled by cnc engraving tooling. In this situation, we need to make electrode and tool the mold by EDM. Mainly electrode material include carbon and copper. Copper electrode cost is higher than carbon electrode. The advantage for copper electrode is that its life longer and not easy broken. So some very very small sizes EDM tooling will use copper electrode.

EDW tooling also used to tool small sizes, but which is 0° angle with straight direction. EDW tooling include slow speed and high speed. This tooling is different with cnc milling tooling and cnc engraving tooling. EDW tooling low speed sizes tooled more precise and cost higher.

4. Deep hole drilling tooling

Normally cooling lines and ejector pins holes are tooled by deep hole drilling tooling. As normal drilling machine tooling, holes may not straight. Therefor, especially for ejector pins holes, not allowed to be tooled by normal drilling machine.

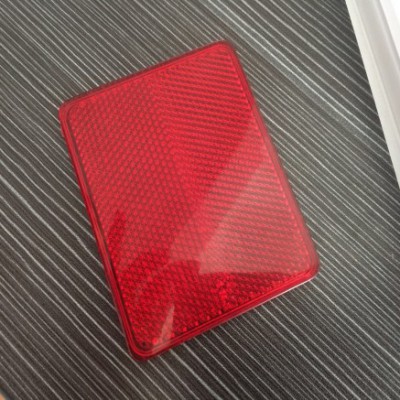

5. PET clear box mould polish

After precise tooling finish and cooling lines and ejector pins holes ready tooled, moulds can be assembled and polished. Auto parts mould need high shinning finish on the part surface, mould polish request is very high. Therefore this mould can't be polished by polishing machine, they need to be polished by manual.